Metal-Arc Fabrication has many assets at our disposal for the many services our customers require. We begin most jobs by discussing the job with the customer to determine the scope of the project and how we can best meet those needs. Once a job is out into the factory we utilize multiple pieces of shop equipment, processes and experience that best allows us to fulfill our customer’s needs. It is our duty to provide the best service and customer experience possible while being competitive in the market place. Our experience in powder coating, welding and fabrication allows Metal-Arc to take an idea from conception to a finished painted product. But you don’t need to stop there. If you have packaging and shipping needs Metal-Arc will successfully assist those needs as well. Whether it is 1 part or 1,000 and made of metal Metal-Arc would like to have the opportunity to work with you.

Powder Coating

A coating that is free from solvent and VOC’s to contaminate the atmosphere. The process applies paint from a fluidized powder electrostacally through a paint gun to a metal surface. The powder is then baked at a high temperature to create fully cured, hard and durable surface. We offer high quality powders and service many industries.

CNC - Computer Numeric Control

The automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. Metal-Arc utilizes CNC machines in two aspects machining and bending. Utilizing machines with CNC capabilities allows us to manufacture a higher tolerance part with greater repeatability than non CNC style machines

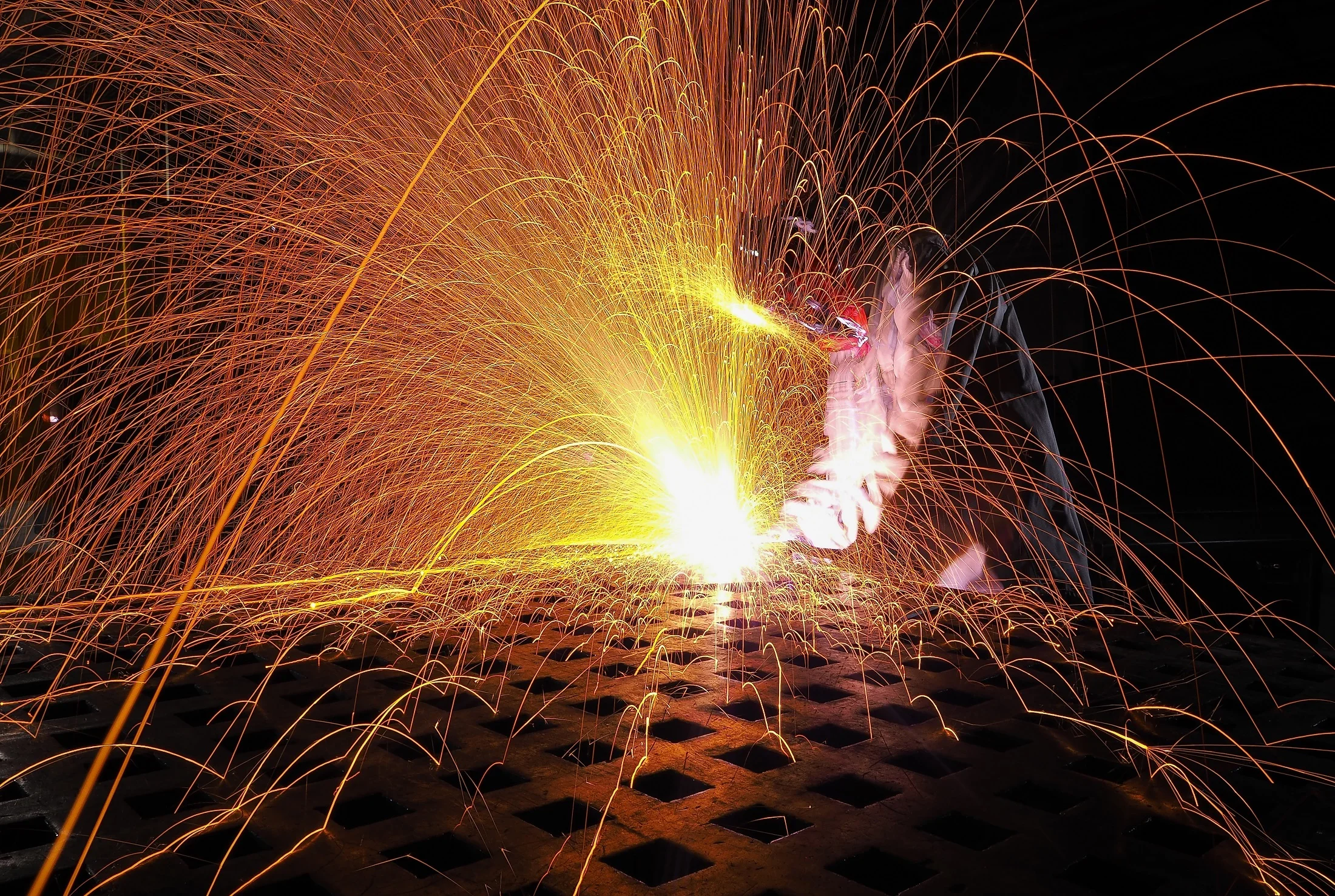

Welding

A fabrication process that joins 2 metal materials together by melting the 2 base metals while adding a filler material to create a joint as strong as or stronger than the base metal. Metal-Arc is capable of welding most base metals including but not limited to mild steel, stainless steel and aluminum.

Bending

A process that takes base metals that are straight and or flat and are cold bent or mandrel bent to create 2 and 3 dimensional shapes.

Saw Cutting, Shearing and Iron working

A process that takes full length material and cuts, shears, chop, or notches to create accurate lengths and shapes.